Amazon Robotics

Custom Tools Team

Amazon Robotics enables global-scale warehouse automation by designing, manufacturing, and managing a fleet of autonomous robots. As a Senior Mechanical Engineer (contracted via Beacon Engineering), I collaborated with field reliability teams to develop custom tools for in-field robot recovery and repair, ensuring operational efficiency and safety. Working primarily independently I developed several notable tools at Amazon, including:

- A novel high-capacity lifting tool to allow easier storage pod realignment by technicians

- An improved ergonomic wheel removal tool to alleviate safety concerns with existing options

- Several retrofits to existing in-field tools to improve ergonomics and safety performance

iRobot

Front End Innovation

My time in the FEI team at iRobot focused on advanced development of novel approaches to existing and anticipated challenges in the wet floor care market space. This includes a focus on leveraging cross-industry innovation and new concepts to improve sanitization and user experience for future projects. I matured technologies that were later used on several docking systems and robot platforms, including:

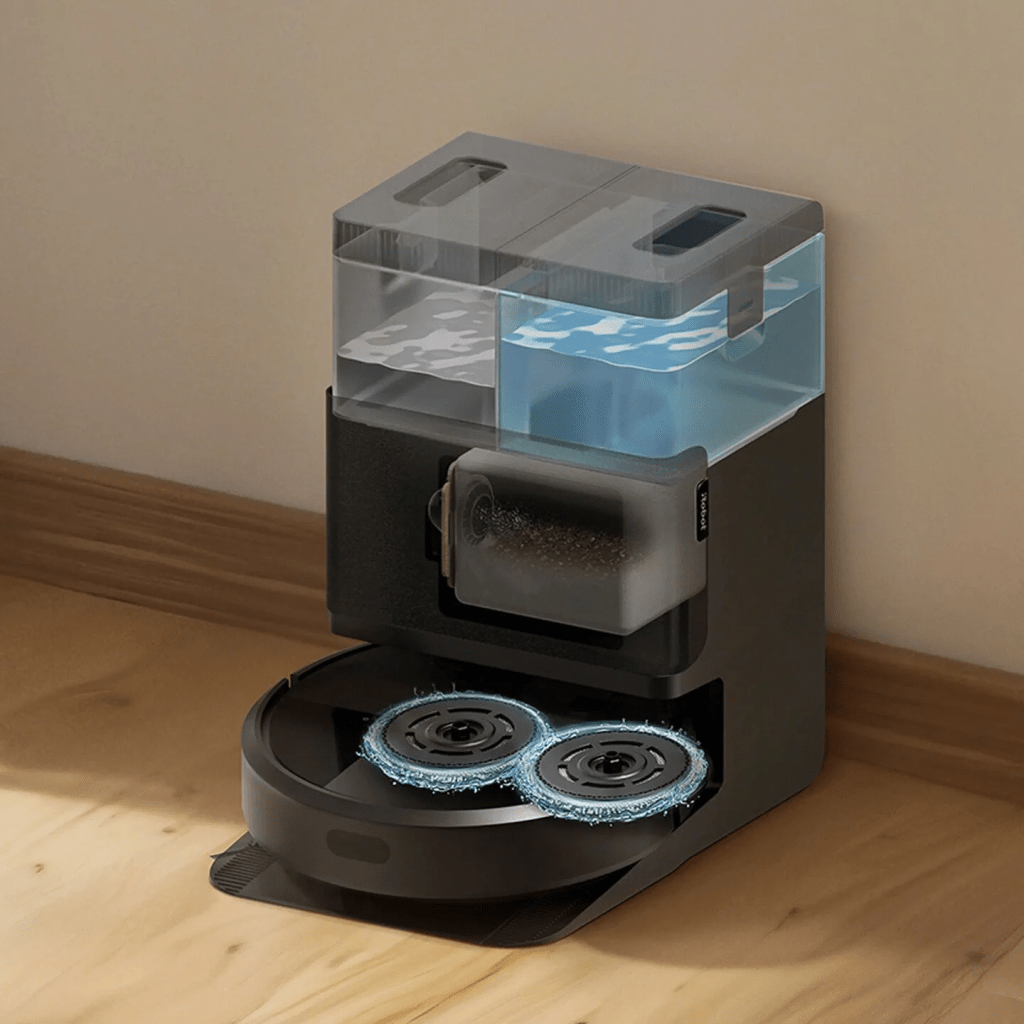

- Roomba Plus 405 Combo Robot + AutoWash Dock

- Roomba Combo 10 Max AutoWash Dock

J9+ Combo Auto-Refill Dock

As part of the J9+ Auto-Refill dock team I took ownership of the ramp and docking subsystems for the entire NPI lifecycle of the product. My work focused on:

- Designing, owning, and supporting through production start of the ramp and docking subsystems

- Combination of injection molded plastic, sheet metal, and machined parts

- Improving docking reliability

- Developing a novel charging contact architecture

- Ensuring safe and reliable handling of water and FOD

- Increasing dock-side traction

Braava Jet M6

I joined the M6 team late in its NPI lifecycle and helped the product cross the finish line and enter sustaining. Once in sustaining, I took ownership of mechanical efforts and led several FA and Cost Down efforts that resulted in $300k+ YOY cost reductions for the program. During this time I designed several notable mechanical improvements to the platform, while also managing a team of JDM supporting engineers from a 3rd party. Notable areas of focus include:

- Peristaltic pump reliability improvements

- Water filtration

- Novel charging contact formulation

- Electronics packaging and moisture protection

- Thermal management

- ID/UX improvements

- Traction and tire design improvements

COVID-19 Work

Emergency PPE production for Brigham & Women’s Hospital, March 2020 – June 2020

I’ve had the privilege of being able to work with a group of fellow iRobot employees in volunteering time and resources to produce emergency PPE as part of the global response to the Coronavirus pandemic. My work on the project has consisted of design-for-manufacturability improvements on an existing face shield designed by incredibly talented medical engineers at MIT, and production and assembly of that design using rapid prototyping technologies available at iRobot. The masks produced are both reusable and effective, and can be seen in news footage here.

RSE

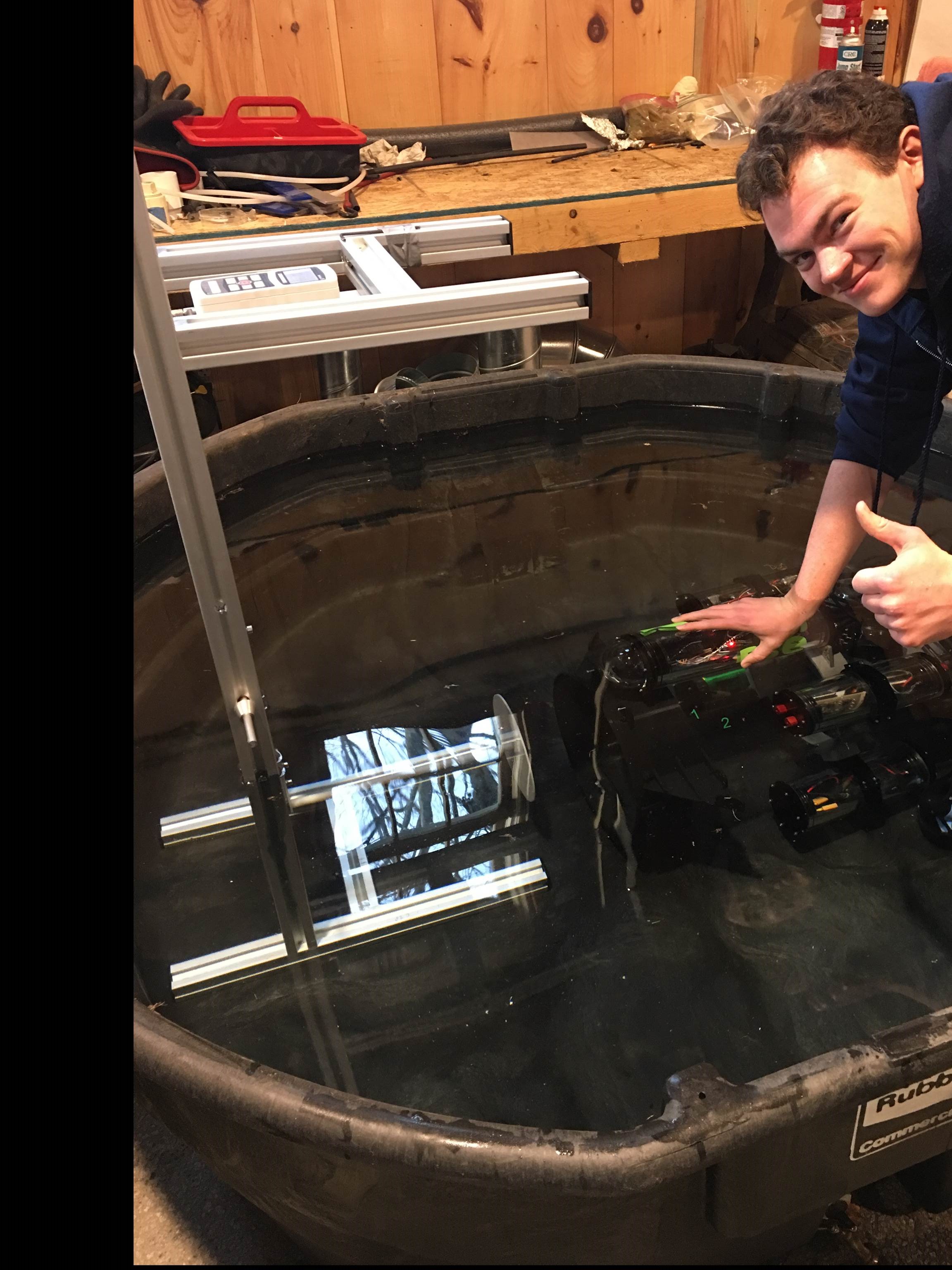

Robots in Service of the Environment Volunteer, December 2018 – 2020

Robots in Service of the Environment is a nonprofit dedicated to solving environmental issues with cleverly applied robotic solutions. The group’s largest project is the Guardian robot, a robot designed to capture invasive Lionfish in the Caribbean. As a member of the team, I’ve been able to support testing and design tasks on the Mark IV, the most recent rendition of the robot. The bulk of my work has involved improvements and testing around fish capture and retention, including suction testing and fish retention feature design. You can read more about the project here.

NASA Langley Research Center

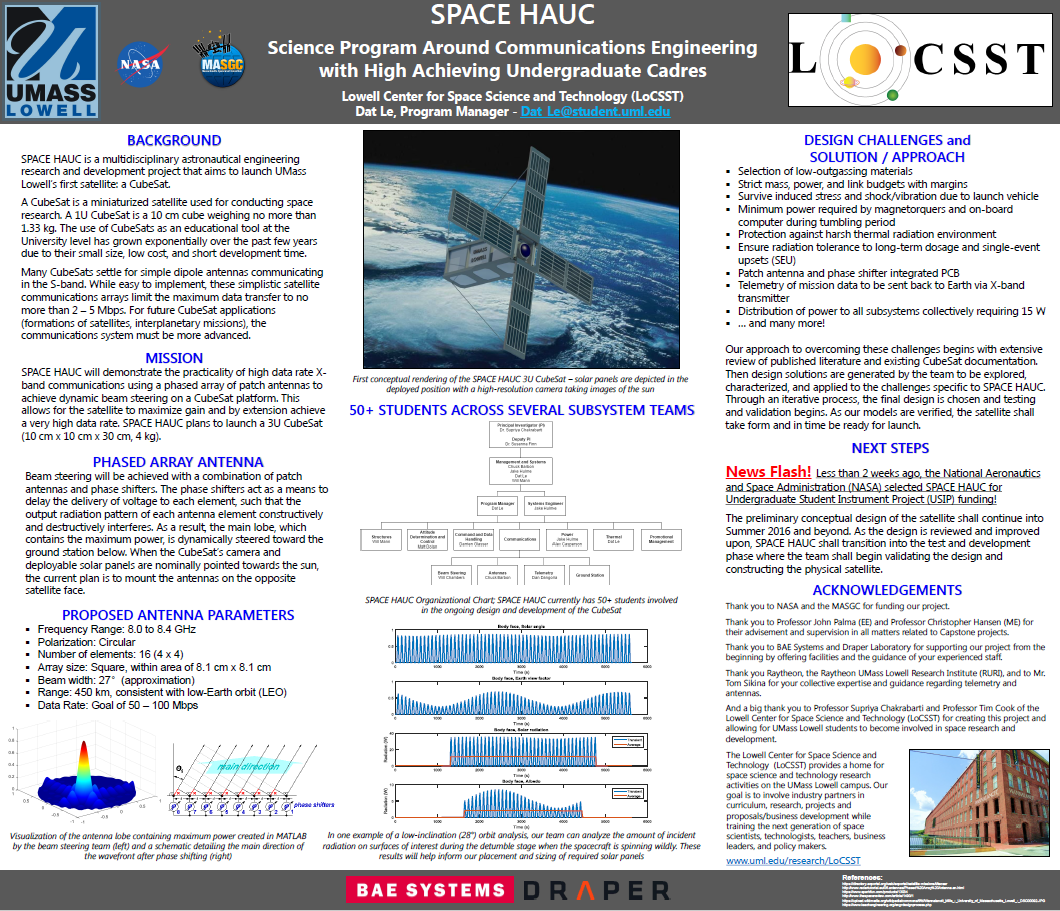

SPACE HAUC

Attitude Control Subsystem Team Lead, February 2016 – May 2017

SPACE HAUC (Science Program Around Communications Engineering with High-Achieving Undergraduate Cadres) is an undergraduate-designed 3U Cubesatellite currently being built at UMass Lowell. As the ADCS team lead, I organized and led an enthusiastic team of programmers, engineers, and physicists working towards controlling the in-orbit motion of SPACE HAUC. The program is a “multi-generational” initiative, as each successive group of undergraduates is responsible for turning it over to future rising juniors and seniors. I was the first ADCS team lead, and as such helped to define the direction our attitude control system would take. More information about the satellite can be seen below.

Quadcopter build

Working with a group of colleagues at NASA Langley, I built and tested a quadcopter in the Fall of 2017. The project was both a fun way to spend our time after work, and an interesting way to apply some practical prototyping and problem-solving skills. We also got to work on some piloting skills, and successfully got the quadcopter through several test flights!